It is possible to ball the end of a stranded steel cable by using TIG welding. The secret: In order to melt the steel cable strands, you have to control the heat flow after a short TIG welding pulse. And that is easy as explained below. The beauty of an end of a steel cable, melted into a ball of steel is that it is rigid and precisely at the position you want.

I broke down a fence and came across this construction I made years ago: This technique is not only fun but also extremely useful. Because I can’t find it anywhere on the web, I am publishing a short post here.

There is also a video, but don’t forget to read the rest.

Table of Contents

Challenge

If you hold a TIG electrode to the end of a steel cable, the wires fly in all directions. I would be very surprised if you manage to make one ball of steel. The uncontrolled heating of the wires melts them to various uncontrolled lengths. Dissapointed, you start buying expensive and labour intensive parts. But hold on!

Solution

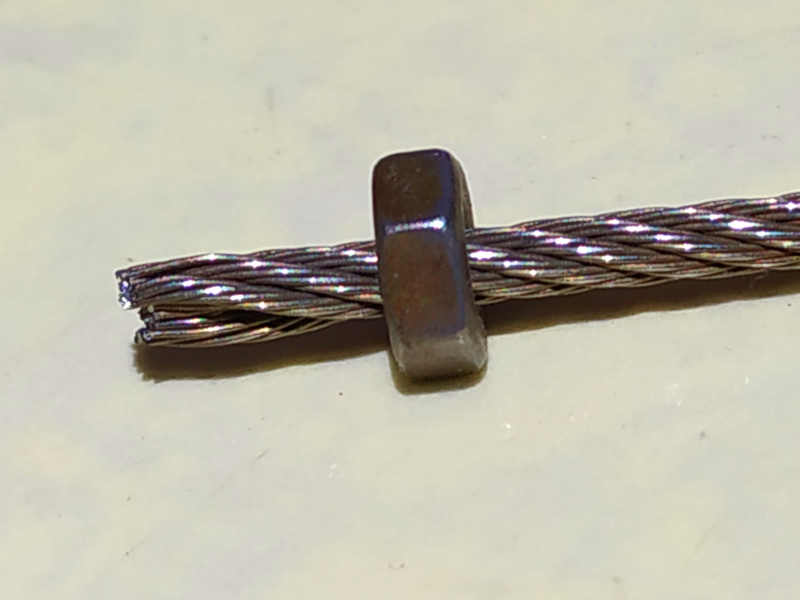

By placing a heat absorber, you gain control over the process. That is the role of the nut. There is a good chance that the nut will get stuck. If you don’t want that, you can use brass or aluminium nuts, washers or plates, for example.

The photos are of a 2 mm stainless steel cable and a M3 nut.

Of course, you will want to do a test first. Choose a very low current.

The free length, before the TIG operation, is about 3 times the diameter of the cable.